Process Industries Simulation

Dynamic simulation for process training and engineering (oil & gas production, gas processing, biogas & LNG, refining, petrochemicals, chemicals, fertilizers, water, hydrogen & renewables)

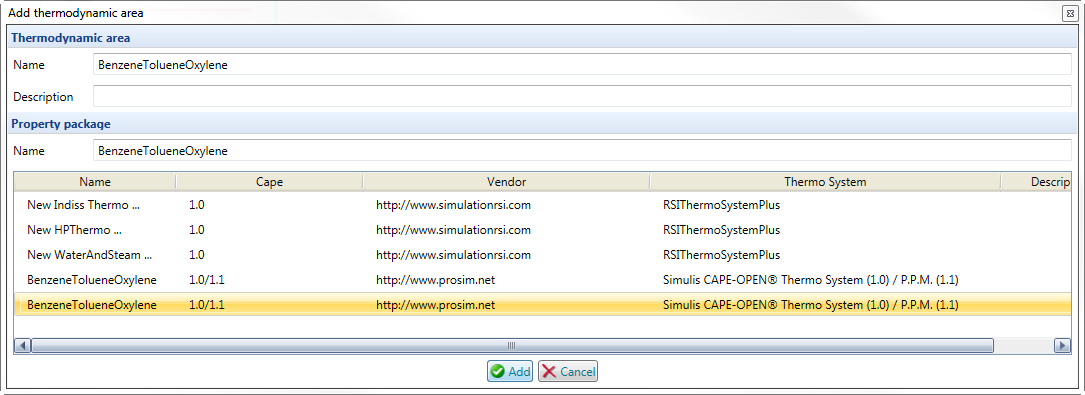

Thermodynamics Packages

The application has a rich library of Thermodynamics Packages, Pure Components, and Unit Operation Modules. However, if 3rd party proprietary components, thermodynamics packages or chemical reactor models are required they can be seamlessly integrated within the INDISS PLUS® platform by taking advantage of the multi-layer component architecture.

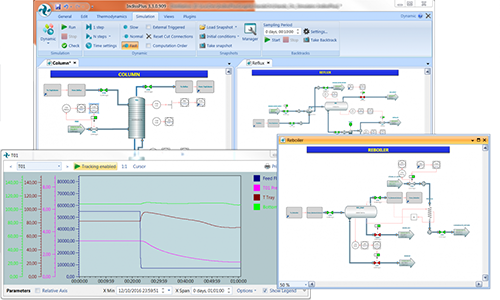

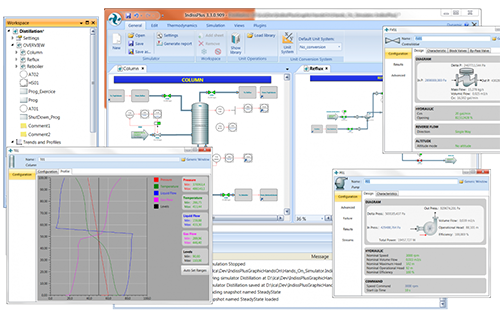

Process Diagram Builder

Unit Operation detail can easily be specified through each Unit Operation’s Faceplate by filling in the appropriate information in the form of a datasheet

Unit Operation Faceplates

INDISS PLUS® incorporates a Unit Operation Faceplates (based on Microsoft .NET Framework) to enable users to interactively build their flowsheets using the menus, dropdowns or drag and drop capabilities

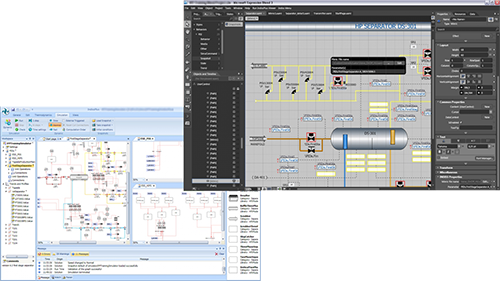

New and Improved Architecture

new features available as a result of INDISS PLUS® architecture updates, including:

• Custom ribbon toolbar included in the model builder, as well as instructor and field operator stations

• Memory improvements to improve speed of simulation

• Advanced multi-thread execution capability that allows for parallel processing on computer hardware.

• Web-based capability to allow for remote server operation of simulations via thin clients over intranets and the Internet for Software as a Service (SaaS)

• Enhanced open environment for easier integration to 3rd party packages such as CAPE-OPEN.

• New DCS operator console emulations.

• Advanced trending and historization capability

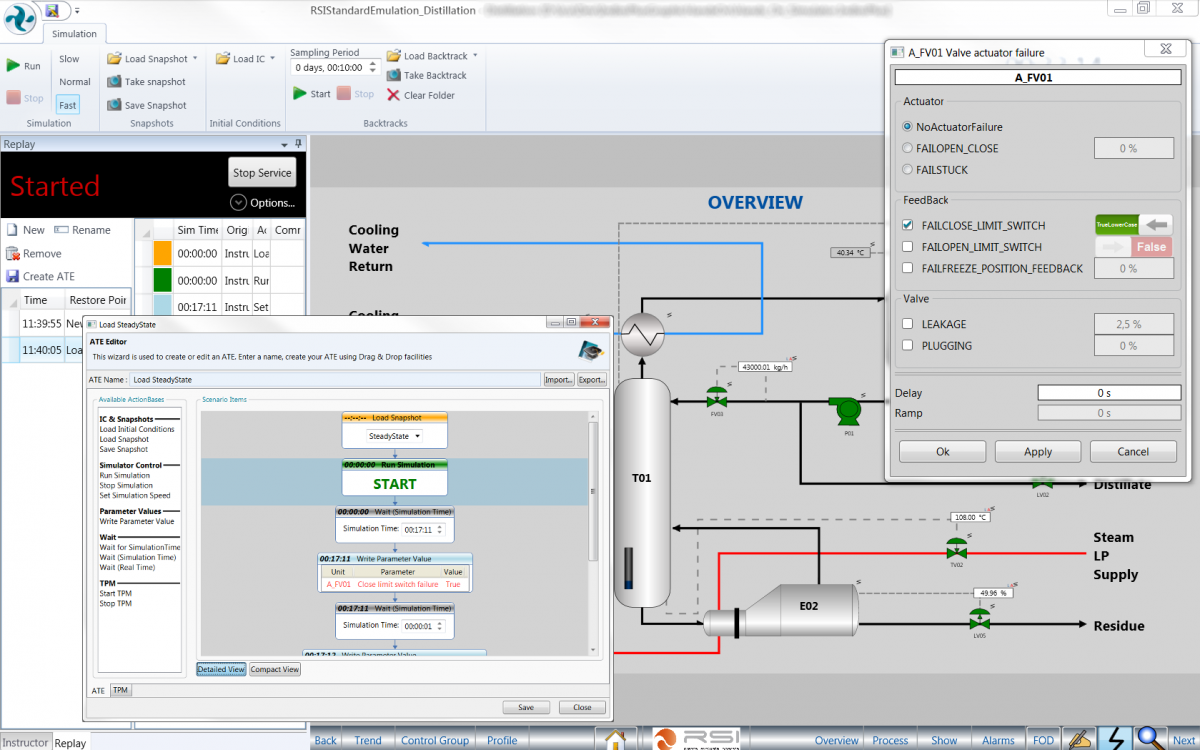

Instructor Viewer Console

From the INDISS PLUS® Viewer Console, the Instructor can call up displays, load models, insert malfunctions, and perform other tasks during a training session. The interface is based on plant and simulator specific graphic displays. Through these displays, the User can monitor the status of the models and directly control selected malfunctions. The Instructor will also use the instructor station to work on predefined scenarios and exercises for trainee evaluation. Scenarios are called ATE for Automatic Training exercise and evaluation is done using TPM for Trainee Performance Monitor. The INDISS PLUS® OTS can be easily deployed on the intranet network and connected to centralized training management system (LMS) via SCORM).